Once plastics were invented in early 1900’s, using plastics and making plastic products has become an inseparable part of how humankind in expanding the boundaries of creativity. Plastics have revolutionized product manufacturing by replacing other materials. Plastics are now everywhere and will be a part of our lives forever.

Plastic injection molding is playing a big part in this plastic revolution. Injection molded parts are in virtually any product you buy from stores. Looking at the vast amount of plastic parts that are assembled together to make products you might think what can be done to make them eco-friendlier. How to make products in a more sustainable way? But injection molding is injection molding, then apply secondary operations to make all look good? Right?

Not necessarily. Imagine,

If you didn’t have to paint the parts to hide molding defects?

If you could reduce the use of materials at the same time?

If you could also greatly increase the content of recycled material?

This and more is possible with high heat molding. It makes a big impact in reaching toward more sustainable, eco-friendly manufacturing of injection molded parts. This method of injection molding is also called ‘Heat and Cool Molding’ or ‘RHCM’ and it can be done with hot water, steam, oil, electrical plugs or by induction. Heating by induction is the fastest, most economical and safest technology for Heat and Cool Molding. Here is shortly listed what makes high heat molding with Roctool induction heating technology more ecological production method.

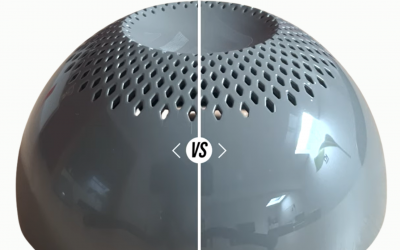

- No paint needed. With Heat and Cool technology (H&C) injection molded parts will have a superior surface finish. Painting is not needed anymore to hide molding defects. Defects will be completely eliminated or drastically reduced.

- Decoration and textures directly from the mold. With up to 97% replication of the mold surface, the part is complete and ready for assembly right after demolding. With laser texturing anything is possible from zero reflection surface to nano-scale holograms. Piano-finish, high-gloss surface directly from the mold is possible even with fiber filled plastics.

- Part lightweighting. Lower part weight and material savings can be achieved reducing the wall thickness and/or by using foaming agents.

- Recycling. Recycling of plastic that is not painted is naturally easier and production time rejects can be reused.

- Using recycled. It is possible to greatly increase the content of recycled material and still achieve premium appearance for the application.

- Eliminate assembly parts. Through high surface replication, assembly parts can be eliminated. High-gloss and low-gloss surfaces can be molded perfectly side by side within the part.

- Faster and effective. Other heating methods are no match for induction and will end up costing more, taking more time and using more energy. Heating with induction will take just seconds and can be embedded into cycle time. With enhanced cooling, there is no production time penalty.

Roctool has perfected the induction-based heat and cool technology. If you want to know more and how it works, please visit our website www.roctool.com. Read also “HD Stories” stories how companies have successfully used our technology to make better products. I’m inviting you to connect with me to receive more detailed information or to start a development project just for your application. At Roctool, molding matters.

Image © Arable – www.arable.com

By Matti Maatta, Senior Designer @ Roctool Inc.