Equipment

Discover ROCTOOL's expertise in feasibility study, engineering, analysis, tool design, components, and installation. Our comprehensive services in plastic injection molding ensure exceptional results and optimize your manufacturing processes

ROCTOOL

1 – Feasibility Study

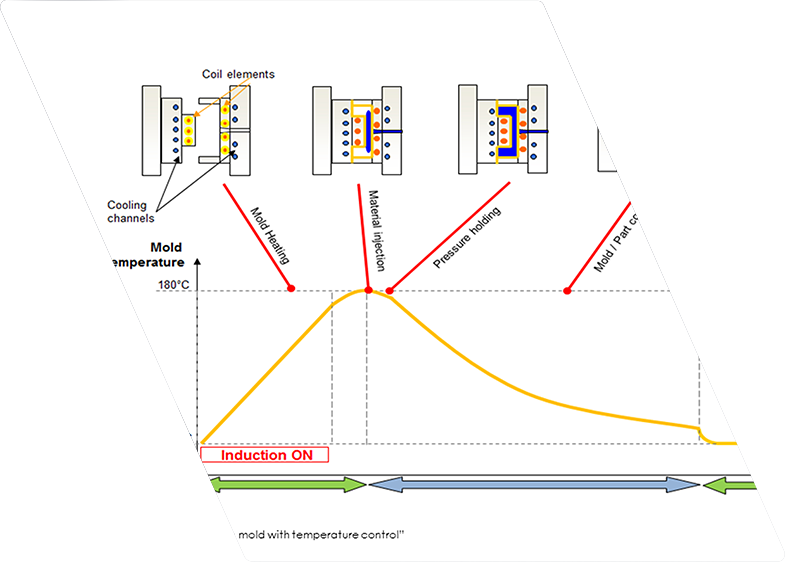

According to your needs, our engineering team will provide you with an evaluation of the 3iTech™ integration in the tool and the capacity to reach your targets using our Heat & Cool technology.

2 – Engineering, Flow Analysis & Tool Design

Our Engineering team will define the most optimized design of Heat & Cool network based on thermal analysis.

For injection process, we can also provide flow analysis in Heat & Cool conditions.

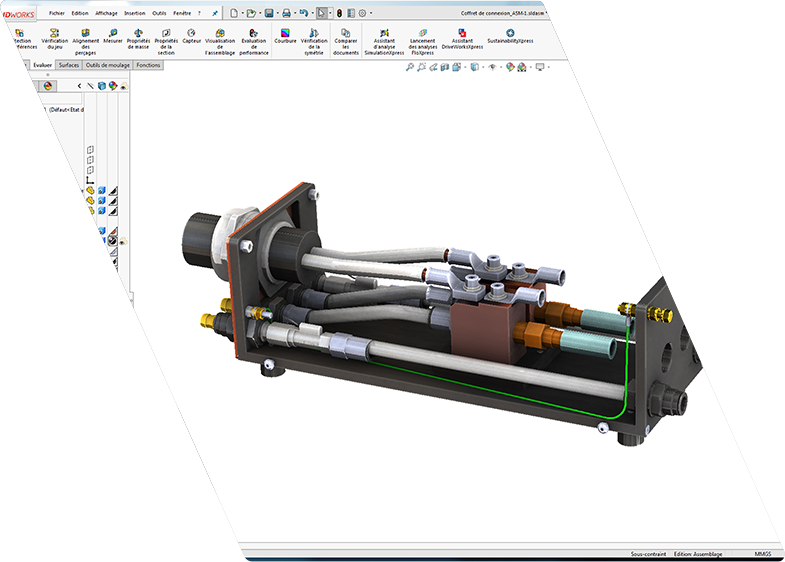

Our CAD team will integrate our 3iTech™ technology in your tool design in collaboration with your tool maker.

3 -Tool Components

We provide the tooling components needed to integrate our technology into your mold. (inductors, connection box, thermocouples etc.)

4 – Induction Generator Systems & Cooling Units

We provide complete turnkey add-on systems to your existing production units ; like induction heating systems, tooling hardware, power units, peripherals.

5 – Installation,Training & Process Start-up

Our team will assist with your installation, commissioning, training and on site support ; including after sales services.

Roctool Services

Heat & Cool Hardware

Our machines tailor-made for your production.

HD Plastics™ Database

High Definition Plastics™ Database is dedicated to OEM’s to quantify the Roctool improvement with injected parts.