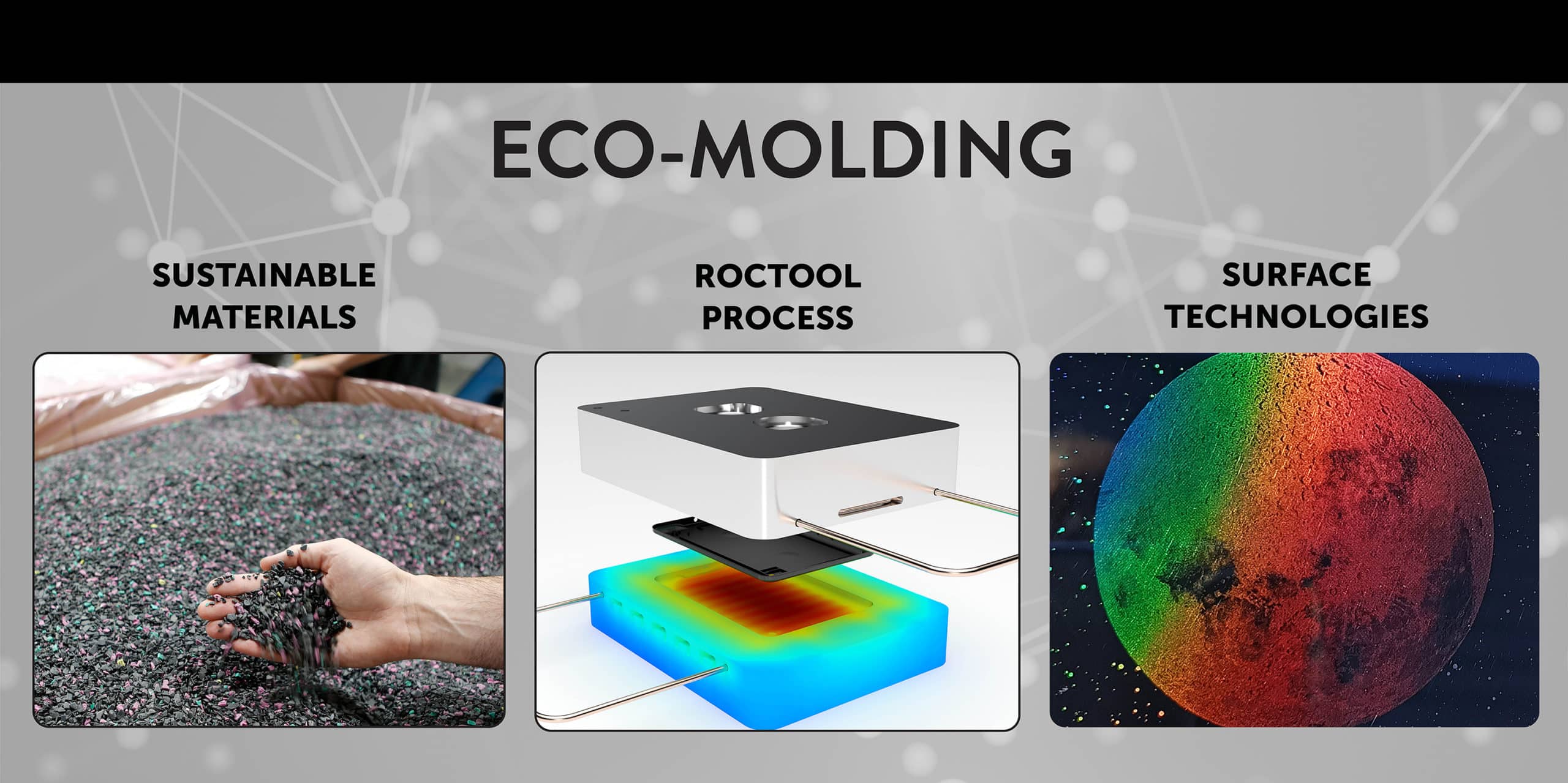

ECO-MOLDING™

Experience the cutting-edge technology of eco-molding, delivering high-quality products with a wide range of options in plastics, composites, and metals. Achieve up to 97.2% tool surface replication for exceptional results.

ROCTOOL

3 Pillars Working Together

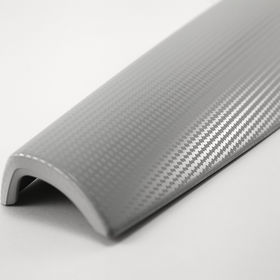

Advanced Surface Technologies

Design Elevation of the finished part.

Next-gen surfaces via laser texturing.

Mix of textures on the same part.

Functional surfaces in tactical areas of the product.

CO2 reduction.

Best Molding Process

High-speed induction heating with cycle time optimization.

Low scrap due to accurate technology therefore higher flow and material savings.

Consistent automatic process.

Avoid all secondary operations including paint, hot stamp & spray.

CO2 reduction.

Sustainable Materials

Increased usage of recycled resins.

Explore the most sustainable resins.

Bio-sourced, reclaimed, natural, recycled, recyclable, and all other materials.

CO2 reduction.

We’re ready to work on a first feasibility

Send us a short brief for the production of your part, we’ll answer you back within the next 48 hours.

ECO-MOLDING™ product examples

ROCTOOL TECHNOLOGY

Heat & Cool system

ECO-MOLDING™

Industry

Stories

Automotive, Aerospace, Electronics, Beauty, Consumer Goods, Medical

Work

with Us

Feasibility Study, Engineering, Analysis & Tool Design, Components, Installation