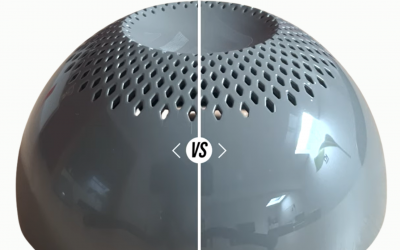

Thank you, Efrat Friedland, for this insightful post! 🌟 Roctool can indeed provide 𝗸𝗲𝘆 𝗮𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲𝘀 for both virgin and recycled materials, such as:

✔️ Defect elimination

✔️ Improved material flow

✔️ No need for secondary operations

✔️ High gloss and low gloss on the same part

✔️ Ultra-surface replication

✔️ Reduced cycle times (depending on resin)

…and so much more! We’re proud to contribute to enhanced sustainability and efficiency in material processing. 💡

https://lnkd.in/eS4uThMf

I am saddened to see over consumption and over production and always advocate recycling and reuse. If you must design a new product, or looking for an alternative for your virgin hashtag#plastics – consider using BLACK recycled and recyclable plastics. Here’s why:

➡️ Black can hide surface irregularities, making imperfections less noticeable.

➡️ Black pigments, especially carbon black, effectively block UV light.

➡️ Black plastics are used across industries servicing many applications.Despite the benefits, challenges like limited hashtag#recyclability of black plastics due to optical sorting issues (e.g., traditional recycling systems struggle to detect black pigments) should be addressed. Innovations like using near-infrared (hashtag#NIR) detectable pigments are helping mitigate this issue.

⭐ For high gloss or deep matte hashtag#surfaces with 100% recycled plastics, check Roctool technology: https://lnkd.in/ddQMXx6c

This will help you avoid secondary treatments (painting, lacquering) to facilitate future recyclability.