In recent months, Roctool will have accelerated its work on current topics of interest: material analysis, injection trials, comparisons, data archives, etc. this applied research phase will allow the company to anticipate current projects and hone the Roctool Beauty Solutions offer for tomorrow, with eco-responsibility always in sight.

During this last semester, Roctool has built partnerships and relationships with brands as well as certain manufacturers towards the priority areas; such as design & aesthetics, (reduction of secondary operations, visible defects etc.) The elimination of paint adds an economic as well as an environmental argument, as does the use of recycled, bio based and biodegradable resins. Furthermore, each of these areas justify Roctool doing extensive trials and testing to each specific development.

Conclusive trials on PET & PCR PP but not only.

In order to satisfy the double priority for brands, both aesthetic and environmental, Roctool focuses its efforts on the materials trials and their injection behavior.

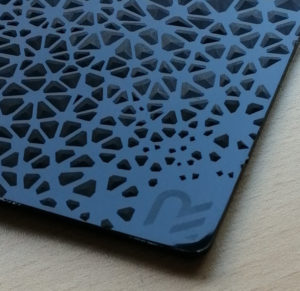

The latest studies have focused on PCR PP, PCR ABS and PCR PET, they compared conventional injected parts with Roctool technology, eg. PCR PET resulting from the recycling of bottles is suitable for good quality injection. With Roctool technology, the part presents a surface appearance without defects or weld lines, whether it is a Matt or Glossy finish, the replication of the mold is optimal and directly challenges the equivalent finishes obtained by painting.

Example – PCR PP with Roctool Technology

Roctool is also making progress in assessing the advantages for producing thin-walled parts or reducing pressure during molding. For example, at an equal pressure, certain PCR materials injected using Roctool Technology allow to fill the part to 100% at 110°C against 30°C in conventional molding and only filling to 70%. In order for conventional molding to reach 100% filling, it would require such pressures that would make the manufacturing process difficult.

The biodegradable and bio based resins currently being studied promise convincing results, both in terms of surface quality obtained and process stability.

As every material has different characteristics, Roctool will continue its in-depth work in order to quantify the maximum amount of eco-responsible materials that are available on the market and to push its expertise at the service of major brands and their suppliers.