Click here for Premium Beauty News article

Focus on new materials

Beauty brands favor recycled, organic or bio-based materials, while not compromising on quality and aesthetics.

However, these “non-homogeneous” materials (mixture of different batches, impurities and colors, etc.) often present difficulties during processing (appearance defects and moldability). The industrial challenge then lies in the search for stable processes.

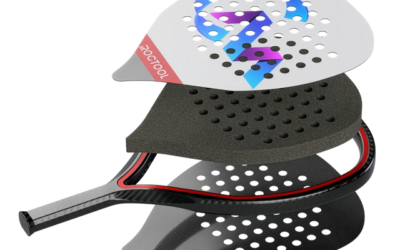

Roctool Innovation

Throughout the years, Roctool has developed a unique know-how on surface quality with its Heat & Cool technology that transforms sustainable resins into nothing short of exceptional.

How? By heating the mold by induction, this innovative process allows better flow of the materials inside the mold. It eliminates defects such as: weld lines, shrinkage and blush, regardless whether the parts are thin or thick. Roctool technology also optimizes glossy or matt finishes, different contrasts and textures, via the Ultra Surface Replication™ of up to 97.2% (depending on the material used).

Faced with the challenges of increasingly responsible packaging, Roctool’s innovative Heat & Cool technology makes it possible to obtain parts of remarkable quality (glossy, high-quality appearance and replication, etc.) heating the mold by induction. Particularly suited to recyclable, recycled and bio-based materials, Roctool technology facilitates injection molding, reduces injection pressure and reduces or eliminates secondary operations. A significant ecological gain.

A reduced carbon footprint

Improving the general condition of the part means there is no need for secondary operations, such as spray or paint which are often used to hide defects that are deemed “unacceptable” by brands. Therefore, doubling the environmental performance.