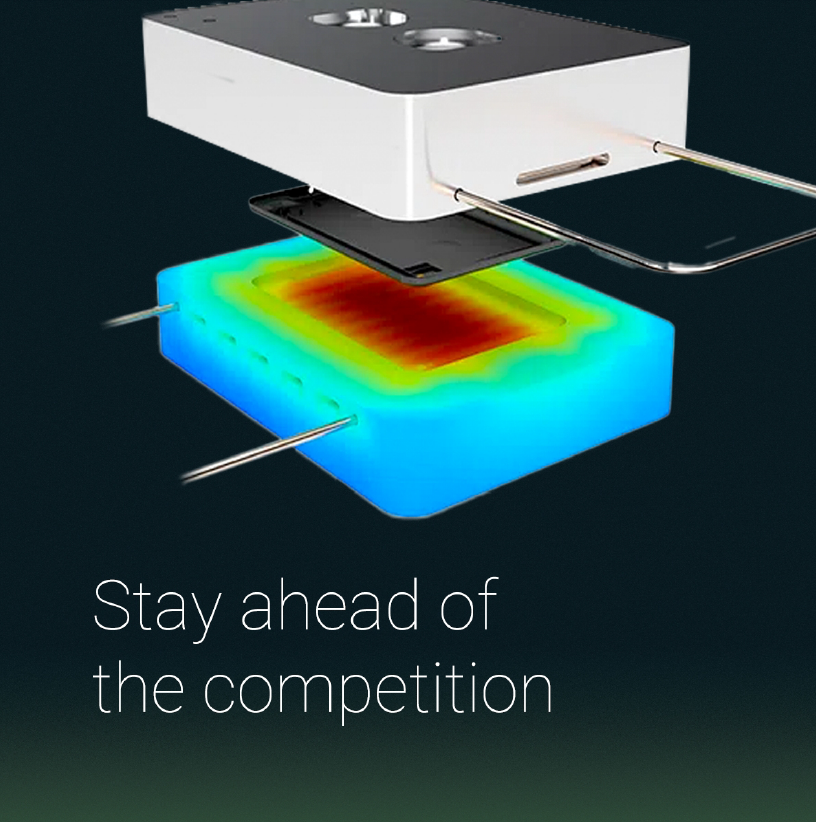

… and molding is no exception. Roctool, together with ENRX Group, has developed electrified molding using induction.

An efficient and eco-friendly technology, with an energy savings potential of up to 50% compared to traditional molding technologies. ⚡

So, should you change? Timing is key in investment decisions. However, every day you wait is another day gained for a competitor who decided to go for it.

Right now, Roctool and ENRX are becoming even stronger together in terms of technology and worldwide representation, as ENRX is acquiring a part of Roctool.

When you choose to outperform competitors, the opportunity is right around the corner.