💡 Roctool’s heat & cool induction molding technology is all about flexibility and precision. One optional feature that can make a big difference? The generator switch.

This switch isn’t required in every setup, but when included, it helps fine-tune the heating phase, especially in demanding or high-performance applications. It gives even more control over the process, ensuring the temperature ramps up at the right time.

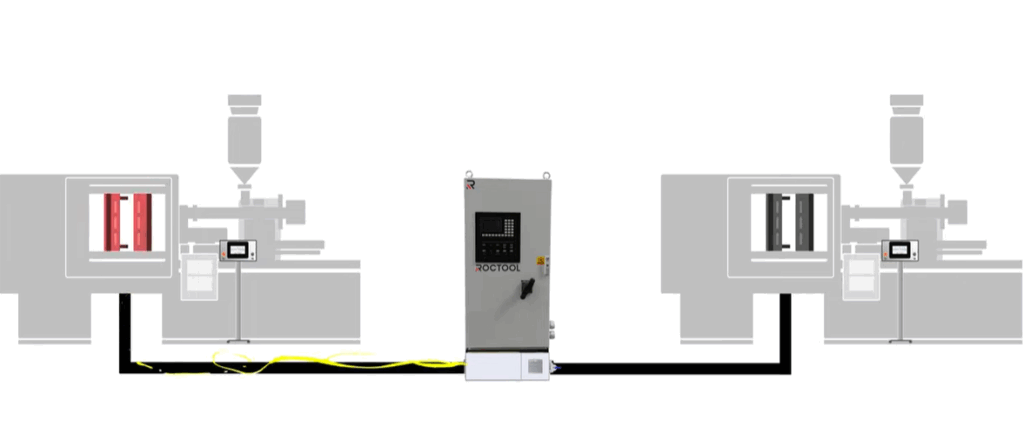

✨ And here’s a 𝘀𝗺𝗮𝗿𝘁 𝗯𝗼𝗻𝘂𝘀: 𝗼𝗻𝗲 𝗽𝗼𝘄𝗲𝗿 𝘀𝗼𝘂𝗿𝗰𝗲 𝗰𝗮𝗻 𝗯𝗲 𝘀𝗵𝗮𝗿𝗲𝗱 𝗯𝗲𝘁𝘄𝗲𝗲𝗻 𝘁𝘄𝗼 𝗶𝗻𝗷𝗲𝗰𝘁𝗶𝗼𝗻 𝗺𝗼𝗹𝗱𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲𝘀 (IMMs). That means better energy management and a more compact setup on the production floor.

The benefits:

✅ Greater process control

✅ Fast switching

✅ Optimized energy usage

✅ Reduced footprint

It’s just one of many options in the Roctool ecosystem that makes the technology adaptable to different production needs, from faster cycles to cost reduction goals.

🔁 Customization matters. One size doesn’t fit all.

🎥 Check it out in action https://lnkd.in/ea3fcmQh