Thank you Herwig Juster for this post. Roctool will be molding PEEK again today in Hall 15, C41.

🔥 For a perfect part out of PEEK, what mold temperature should be used?

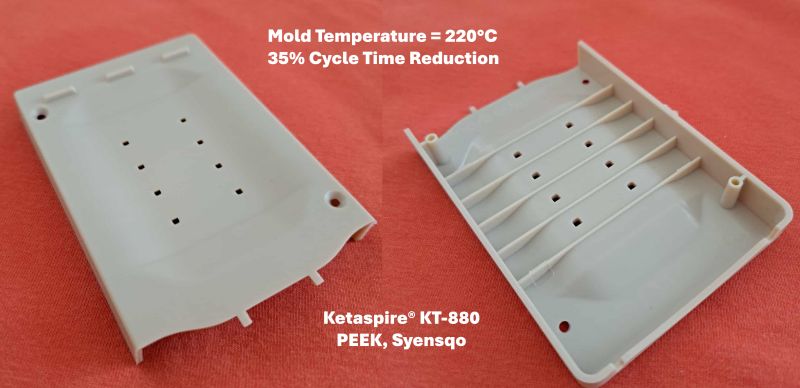

Last week I had the chance to witness an impressive live demonstration of moulding a housing out of Syensqo’s Ketaspire® PEEK KT-880 at the Roctool booth during K Fair —and the results speak for themselves!

📌 Using Roctool’s air-cooled generators, they achieved a mold surface temperature of 220°C during injection, delivering exceptional mold replication with flawless surfaces—no defects or weld lines in sight.

⏰ Even more impressive: cycle times were slashed by 35%, dropping from 85 seconds (without Roctool) to just 55 seconds with their technology. The result? Perfect texture and gloss replication, zero shrinkage.

And it gets better—even at the recommended mold temperature of 180°C, Roctool technology reduced cycle time from 60 to 40 seconds!

If you’re at K Fair, don’t miss this innovation in action. Check out Ketaspire® Hall 6, C61 and Roctool in Hall 15, C41!