What if assembly became part of the molding process? With Roctool Thermal Fusion™ (RTF™), manufacturers can achieve true thermoplastic composite integration—reducing part count, simplifying production steps, and enhancing surface quality. Discover the technology live at JEC World 2026.

Innovation

ROCTOOL

Process Efficiency & Control

Roctool’s induction heat and cool technology enables precise temperature control and stable processing across every cycle. Manufacturers benefit from consistent surface quality, reduced scrap rates, and shorter, predictable cycle times—driving measurable gains in process efficiency and production reliability.

PP & GF with high gloss

What you see here is PP + GF. No tricks. No paint. Just Roctool Technology delivering surface quality that conventional molding just can’t match. ✅High gloss, sharp textures, and...

Article from Herwig Juster for Roctool and Syensqo

Thank you Herwig Juster for this post. Roctool will be molding PEEK again today in Hall 15, C41. 🔥 For a perfect part out of PEEK, what mold temperature should be used? Last week...

Live demo with SABIC

☀️ Day 5, Yes, Even on Sunday! ☀️ We’re back at it, molding PEI + 30% GF from SABIC live on the booth, high heat, high performance, zero weekend breaks. 📍 Hall 15, C41...

High Heat Molding at K-2025

Day 3 at K – The World's No.1 Trade Fair for Plastics and Rubber. Come and see our HIGH HEAT live demo with PEEK from Syensqo today and Monday at Hall 15, C41....

K-Show – Roctool presenting high temperature molding demos

✨Exciting news from Roctool ! At K – The World's No.1 Trade Fair for Plastics and Rubber 2025 in Düsseldorf, we will present live high-temperature molding demonstrations,...

𝗨𝗹𝘁𝗿𝗮 𝗦𝘂𝗿𝗳𝗮𝗰𝗲 𝗥𝗲𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻™

🔍 Ultra Precision. Zero Compromise. At Roctool, we don’t just mold parts, we replicate the finest details with 𝗨𝗹𝘁𝗿𝗮 𝗦𝘂𝗿𝗳𝗮𝗰𝗲 𝗥𝗲𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻™ (𝗨𝗦𝗥™). From velvet-like textures that...

Let’s heat things up intelligently!

𝗣𝘂𝘀𝗵𝗶𝗻𝗴 𝘁𝗵𝗲 𝗟𝗶𝗺𝗶𝘁𝘀 𝗼𝗳 𝗖𝗼𝗺𝗽𝗼𝘀𝗶𝘁𝗲 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 with Roctool 🔥 At Roctool, we're transforming compression molding by pairing advanced induction heating with the versatility of 𝗥𝗧𝗠...

Time to unplug the past!

🔥 Still using oil or cartridge heaters in 2025? Time to unplug the past. Let’s be honest, oil heating and electric cartridges for compression molding are slow, inefficient, and...

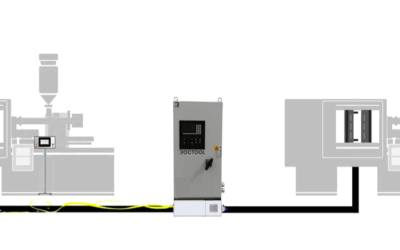

𝗢𝗻𝗲 𝗽𝗼𝘄𝗲𝗿 𝘀𝗼𝘂𝗿𝗰𝗲 𝗰𝗮𝗻 𝗯𝗲 𝘀𝗵𝗮𝗿𝗲𝗱 𝗯𝗲𝘁𝘄𝗲𝗲𝗻 𝘁𝘄𝗼 𝗶𝗻𝗷𝗲𝗰𝘁𝗶𝗼𝗻 𝗺𝗼𝗹𝗱𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲𝘀

💡 Roctool’s heat & cool induction molding technology is all about flexibility and precision. One optional feature that can make a big difference? The generator switch. This...

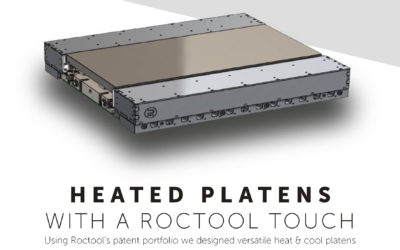

R-IDS™ (Roctool Induction Dynamic Saver)

🚀 Sharing a closer look at one of Roctool’s latest innovations: the R-IDS™ (Roctool Induction Dynamic Saver)! https://lnkd.in/ePcDTaYf These heated platens are setting a new...

ROCTOOL TECHNOLOGY

Heat & Cool system

ECO-MOLDING™

Industry

Stories

Automotive, Aerospace, Electronics, Beauty, Consumer Goods, Medical

Work

with Us

Feasibility Study, Engineering, Analysis & Tool Design, Components, Installation