Heat & Cool for Compression Molding

Unlock the potential of heat & cool technology in compression molding. Enhance efficiency, optimize cycle times, and achieve exceptional quality with precise temperature control and advanced techniques.

ROCTOOL

Control. Speed. Quality.

Induction heating has no match when it comes to heating molds for composite materials. Total process control, no heating limitations and quick cycle time.

LIT™ Light Induction Tooling

Enabling an accurate Out Of Autoclave process – OOA

Roctool launched LIT™ (Light Induction Tooling), a turnkey solution which eliminates the need for high cost capital equipment such as autoclaves and compression molding presses. This process uses shell tooling with induction heating which allows high heat and cooling ramps while maintaining high temperature uniformity on the mold surface. Exceeding aeronautical & automotive performances along with very large mold size capabilities results in an overall superior solution.

IDH™ Induction Dual Heating

Hybrid Technology for Composites Processing & Plastic Injection

From raw materials to finished product with decoration in 60 second cycle time. Lightweighting with carbon fiber composites and added functionality with overmolded 3D details.

3iTech® Heat & Cool Integration

Fast and localized heating

Roctool’s patented technology consists of designing a Heat & Cool layout in order to provide a fast and homogeneous heating. Flexible inductors will allow to follow any complex shape of tooling, while using any metallic alloys from standard steel to more marginal alloys as invar for dedicated applications. A high frequency current will be generated to run through the inductors, creating eddy currents and joule effect to heat up the mold surface.

Using standard cooling channels with water and ensuring a fully turbulent flow rate enables efficient cooling of the tool.

Compression Molding Advantages

Dedicated to Large Productions

Roctool technology enables very quick heat ramps with induction, and performance cooling with turbulent water flows. Lowering the energy consumption and limiting secondary operations, Roctool process also fits in smaller footprints.

Accurate Temperatures up to +450°C / 842°F

With virtually no temperature limit, the induction technology is adapted to any composite materials. High temperature homogeneity and multi-zone heating are also achievable through the technology and reinforced with our engineering.

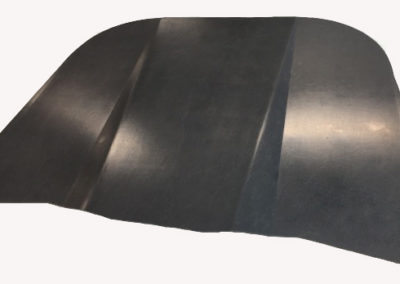

Lightweighting & Complex Geometries

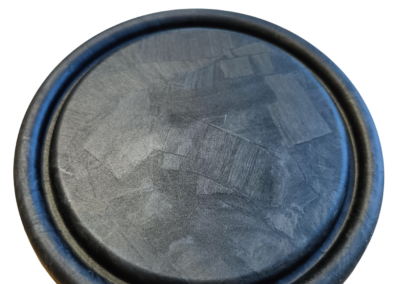

Proved to reach very low void content and high consolidation levels, Roctool Heat & Cool provides the highest performances for composite parts. It can also mold net shape products, structural details such as bosses and ribs.

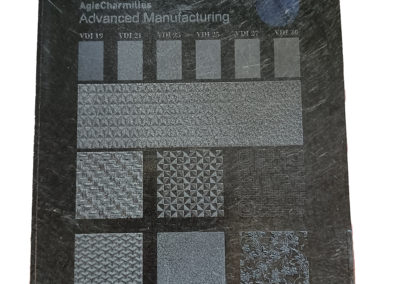

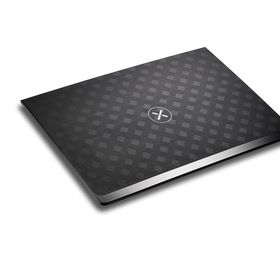

Unique Surface Quality & Design

Adding heat provides resin rich surfaces for higher aesthetics, ranging from high gloss to complex texturation. Accurate temperature distribution also enables the addition of sensitive design orientated materials, (wood, denim, couture fabrics etc.).

Complete Range of Turn-key Solutions

Roctool developed from standard equipment, custom solutions for composites processing:

Light Induction Tooling (view video here)

and Induction Dual heating (view video here)

Adapted for all Composite Materials

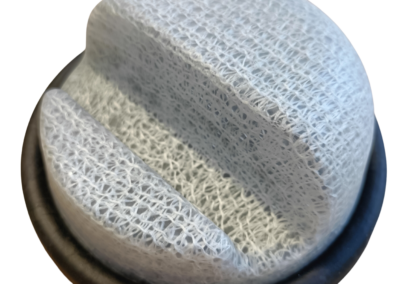

Without any process limitations, Roctool can mold even the most difficult products including recycled carbon non-wovens and carbon/PEEK. It is well adapted to thermoset resins, thermoplastic composites and to sandwich structures.

We’re ready to work on a first feasibility

Send us a short brief for the production of your part, we’ll answer you back within the next 48 hours.

Compression molding product examples

ROCTOOL TECHNOLOGY

Heat & Cool system

ECO-MOLDING™

Industry

Stories

Automotive, Aerospace, Electronics, Beauty, Consumer Goods, Medical

Work

with Us

Feasibility Study, Engineering, Analysis & Tool Design, Components, Installation